Submersible Ejector Pump KIRA EP Series are used in wastewater treatment, supplies the oxygen to a slurry treatment tank and Aquaculture farm, oxygen supply for water tank. Submersible Ejector Pump KIRA EP Series produces the maximum amount of small air bubbles, which increases the rate of oxygen supply.

Work Principle

– Submersible Ejector Pump KIRA EP Series is equipped with specific accessories to create jet power. When pump works, it generates high pressure pushing liquid through the narrow tube in special nozzle. This jet power creates strong current and negative pressure at the same time.

– Special nozzle connects with air pipe up to surface of water. This negative pressure pulls air through pipe into nozzle which functions to be mixing chamber. This nozzle presses air into lots of small bubble and mix into liquid.

– Liquid with small bubble is pressured through expansion pipe and, at last, flushed outside causing best circulation and creating oxygen supply.

– All submersible ejector can matched with the guide rail system for easy installation and maintenance.

Applications

– Pre-aeration and mixing in wastewater treatment system.

– Oxygen supply to a slurry treatment tank Air supply to aquaculture farm or fish pond.

– Air supply to aquaculture farm or fish pond.

Product Feature

– High Solids Epoxy Coating

High solids epoxy coating is used to provide good resistance to wastewater, water contain chemical* or sea water*. Epoxy coating reduces speed of corrosion and extends life span of pump

*Resistance is up to mild level of chemical and sea water. Please consult your dealer for intense level liquid.

– Epoxy Cable Base

All cables are seals firmly by rubber cup and filled with thick layer of epoxy resin at the cable entry. This expoxy resin prevents moisture entering through cable into motor caused by suction force in motor chamber.

– Motor Protector

The motor protector will be activated and cut power off automatically when motor run in abnormal electric current or temperature. This auto-cut protector will be self reset the motor when it returns to normal. The auto-cut protector is installed in the motor and no outside connection required. It is standard equipment in pump up to 7.5 kW.

– Food Grade Lubricant

All pumps are filled with non toxic lubricant to follow company philosophy “JUNSUI” or pure water for good environment. This lubricant is food grade FDA standard, eco friendly and low impact on aquaculture farming.

– Mechanical Seal

All pumps are equipped with double mechanical seal. Strong abrasion resistant mechanical seal composes of best grade silicon carbide to ensure the best seal performance.

– High Efficiency Dry Motor

All stator coils are insulated by quality varnish under the automatic production line. This ensures the best insulation and durability.

EJECTOR

EJECTOR

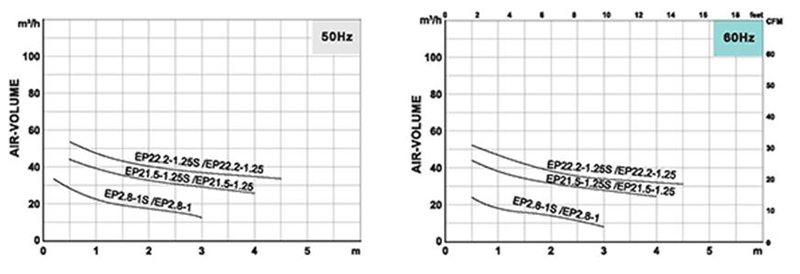

| Model | Motor Output | Air-inlet Bore | Air Volume Depth | Max Water Depth | Capacitor | Solid Passage | Weight kg | Cable | Tank Max Dimension (m.) | Acessories | |||||

| 1Ø | 3Ø | kW | mm (inch) | m³/h (m) | Max Water | m³/h | mm | 1Ø | 3Ø | m | Length | Width | Height | Ejector | Guide Rail |

| KIRA EP2.8-1S | KIRA EP2.8-1 | 0.75 | 25(1″) | 15.5(2.5) | 3 | 21 | 20 | 19 | 18 | 8 | 3 | 2 | 3 | BEP-1AP | TEP-1AP |

| KIRA EP21.5-1.25S | KIRA EP21.5-1.25 | 1.5 | 32(1¼”) | 26(3) | 4 | 51 | 20 | 34 | 30 | 8 | 4 | 3.5 | 4 | BEP-11/4BP | TEP-11/4BP |

| KIRA EP22.2-1.25S | KIRA EP22.2-1.25 | 2.2 | 32(1¼”) | 38(3) | 4.5 | 60 | 20 | 37 | 32 | 8 | 5 | 5 | 4.5 | BEP-11/4BP | TEP-11/4BP |

| – | KIRA EP43.7-2 | 3.7 | 50(2″) | 90(3) | 5.5 | 78 | 35 | – | 71 | 8 | 6 | 6 | 5 | BEP-2CP | TEP-2CP |

| – | KIRA EP45.5-2 | 5.5 | 50(2″) | 130(3) | 6 | 132 | 35 | – | 112 | 10 | 7 | 7 | 6 | BEP-2D | TEP-2D |

| Motor | Body | ||

| Frequency | 50/ 60Hz | Impeller | Semi open (Channel) |

| Phase | Three-phase (Single-phase upon request) | FC200 | |

| Motor | Dry submersible induction motor | M.seal | Double mechanical seal |

| 2P (up to 2.2kW)/ 4P (3.7 – 5.5kW) | CA/CE & SiC/SiC | ||

| Insulation | Class B (up to 2.2kW)/ Class F (3.7 – 5.5kW) | Bearing | Ball type |

| Protection | IP68 | Upper Cover | FC200 |

| Protection Device | Auto-cut protector (built-in) | Motor Frame | Stainless steel |

| Application Liquid Temp Waste water, Sewage and Aeration in Farming | Shaft | Stainless steel | |

| 0 – 40 C (32 – 104 F) | Casing | FC200 | |

| Diffuser | Stainless steel | ||

| Cable | VCT or H07RN-F or SJOW/SOW | ||

| Application Liquid Temp Waste water, Sewage and Aeration in Farming | |||

| 0 – 40 C (32 – 104 F) | |||

| 1%” | 1%” | 1%” | 1%” | 1%” | 1%” | 1%” | |

| 10 | 30 | ||||||

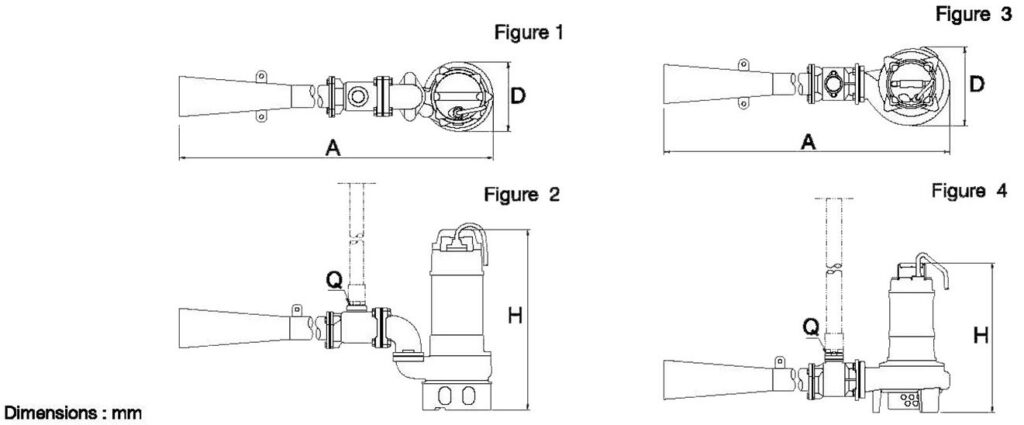

| Ejector | KIRA EP2.8-18 | KIRA EP2.6-1 | 712 | 179 | 450 | 1″ | Figure 1 & Figure 2 |

| KIRA EP21.5-1.256 | KIRA EP21.5-1.25 | 881 | 207 | 520 | 1%” | Figure 3 & Figure 4 | |

| KIRA EP22.2-1.258 | KIRA EP22.2-1.25 | 881 | 207 | 520 | 1%” | Figure 3 & Figure 4 | |

| – | KIRA EP43.7-2 | 1113 | 314 | 638 | 2″ | Figure 3 & Figure 4 | |

| – | KIRA EP45.5-2 | 1380 | 374 | 788 | 2″ | Figure 3 & Figure 4 | |

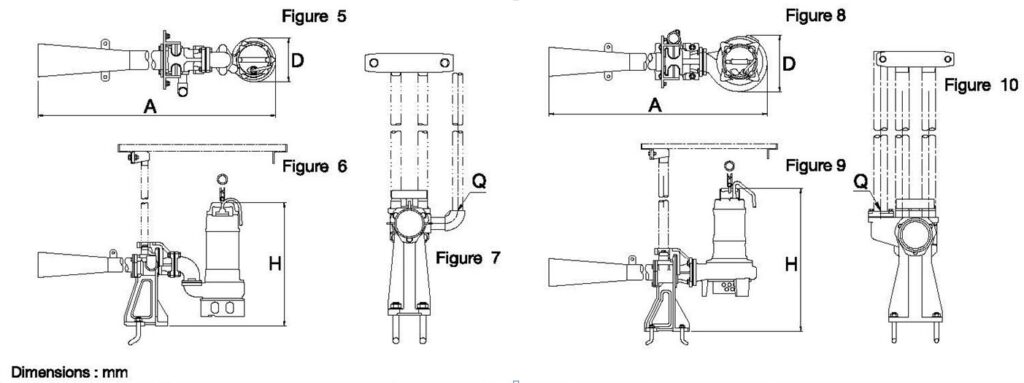

| Guide Rail | KIRA EP2.2-18 | KIRA EP2.8-1 | 742 | 179 | 485 | 1″ | Figure 5 & Figure 6 & Figure 7 |

| KIRA EP21.6-1.269 | KIRA EP21.5-1.25 | 900 | 207 | 590 | 1%” | Figure 8 & Figure 9 & Figure 10 | |

| KIRA EP22.2-1.256 | KIRA EP22.2-1.25 | 800 | 207 | 598 | 1%” | Figure 8 & Figure 9 & Figure 10 | |

| – | KIRA EP43.7-2 | 1133 | 314 | 832 | 2″ | Figure 8 & Figure 9 & Figure 10 | |

| – | KIRA EP45.5-2 | 1402 | 374 | 819 | 2″ | Figure 8 & Figure 9 & Figure 10 | |