The NIBCO® cast iron, wafer style check valve is spring actuated which reduces noise for quiet operation. Check valves prevent backflow by automatically closing when fluid reverses direction.The check valve is recommended for automatic fire sprinkler applications where space is a premium. The check valve is wafer style to fit between standard flanges. The twin disc check valve includes renewable bronze discs. Wafer checks may be installed in horizontal positions (or vertical with flow moving up). Please refer to NIBCO technical data sheets, chemical resistance guides and catalogs for engineering and installation information. Choose NIBCO® check valves for the most specified, versatile and economical valve option in commercial, mechanical and industrial applications.

OVERVIEW

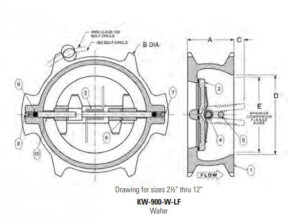

250 psi/17.2 bar non-shock water working pressure (WWP) Spring actuated Renewable disc Rubber seat Double door To be installed between standard Class 125 flanges Wafer connection Use in U.S. drinking water applications is prohibited after January 3, 2014 Listed by Underwriters Laboratories of U.S. and Canada (UL/ULC) FM Approved Size range 2-1/2″ to 16″

| Size | A | B | C | D | E | C/V | Weights | |||||||

| In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | Lbs. | Kg. | |

| 2 1/2 | 65 | 2.38 | 60 | 6 | 152 | 0.125 | 3 | 3.5 | 89 | 1.313 | 33 | 108 | 4.3 | 1.95 |

| 3 | 80 | 2.63 | 67 | 5.63 | 143 | 0.188 | 5 | 3.88 | 98 | 1.688 | 43 | 178 | 6.1 | 2.77 |

| 4 | 100 | 2.63 | 67 | 7.75 | 197 | 0.625 | 16 | 4.75 | 121 | 3.063 | 78 | 440 | 8.8 | 3.99 |

| 5 | 125 | 3.25 | 83 | 7.56 | 192 | 0.813 | 21 | 5.5 | 140 | 3.625 | 92 | 560 | 13 | 5.9 |

| 6 | 150 | 3.75 | 95 | 8.63 | 219 | 0.813 | 21 | 6.25 | 159 | 4.25 | 108 | 840 | 18 | 8.16 |

| 8 | 200 | 5 | 127 | 12.25 | 311 | 1 | 25 | 8 | 203 | 5.5 | 140 | 1600 | 37 | 16.78 |

| 10 | 250 | 5.5 | 140 | 14.75 | 375 | 2.06 | 54 | 10.25 | 257 | 8.5 | 216 | 2700 | 65 | 29.48 |

| 12 | 300 | 7.13 | 181 | 17.38 | 441 | 1.938 | 49 | 12 | 305 | 9.25 | 235 | 4700 | 94 | 42.64 |

| 14 | 350 | 7.25 | 184 | 17.75 | 451 | 3.25 | 83 | 14.38 | – | 12.5 | 330 | 5200 | 200 | 90.75 |

| 16 | 400 | 7.5 | 191 | 20.25 | 514 | 4.5 | 114 | 16.38 | – | 15 | 381 | 7200 | 285 | 129.28 |

| PART | SPECIFICATION |

| 1. Body | Ductile Iron ASTM A536, Grade 65-45-12 – 21/2″ thru 12″ 14″ thru 16″ Cast Iron ASTM 126, Class B w/ Buna-N (Nitrile) resilient seat molded to body |

| 2. Disc | Bronze ASTM B584 Alloy C87600 (21/2″ – 12″) Aluminum Bronze ASTM B148, C95200 (14″-16″) |

| 3. Torsion Spring | Stainless Steel UNS 31600 ASTM A313 |

| 4. Hinge Pin | Stainless Steel UNS 31600 ASTM A276 |

| 5. Stop Pin | Stainless Steel UNS 31600 ASTM A276 |

| 6. Thrust Bearing | Stainless Steel UNS 31600 ASTM A240 |

| 7. Hinge Pin Retainer | Stainless Steel UNS 31600 |

| 8. Stop Pin Retainer | Stainless Steel UNS 31600 |

| 9. Stabilization Sphere | Buna-N |

| 10. Spacer | Stainless Steel UNS S31600 ASTM A276 |