The NIBCO® grooved end NSF Certified butterfly valve provides bubble-tight shutoff at 300 PSI. Grooved ends are compatible with IPS pipe. The valve is ideal in grooved steel pipe systems for commercial and some light industrial process applications, including HVAC, in addition to hot and cold potable water.The NIBCO® ductile iron butterfly valve provides ease of operation with quarter-turn (90 degrees) open to close. The valve features an EPDM encapsulated ductile iron disc. The internal stem/disc splined drive design eliminates the need for pins or bolts that may create leak paths or turbulence in the waterway.

OVERVIEW

Valve pressure rating 300 psi (2″ to 10″); 200 psi (12″ only) Max temperature rating 200°F Grooved style EPDM encapsulated ductile iron disc Stainless steel stem with metal bushings Splined drive Extended neck Operating mechanism: Bare stem, infinite position plate and lock, lever lock, manual gear operator Not recommended for steam service Certified to NSF/ANSI-61-8 and NSF/ANSI-372 Designed to meet MSS SP-67 MSS SP-25 (markings) Size range 2-1/2″ to 10″

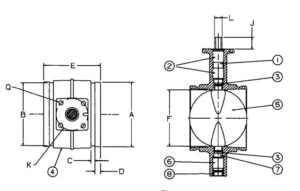

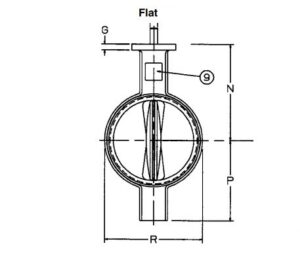

| Size | A | B | C | D | E | F | G | J | K | L | M | N | P | Q | R | Weights | ||

| In. | mm. | Lbs. | Kg. | |||||||||||||||

| 2 | 50 | 2.38 | 2.32 | 0.33 | 0.63 | 3.33 | 2.42 | 0.46 | 1.31 | 3.25 | 0.5 | 0.37 | 4 | 3.14 | 0.437 | 2.89 | 6.7 | 3 |

| 2 1/2 | 65 | 2.88 | 2.72 | 0.31 | 0.63 | 3.85 | 2.42 | 0.46 | 1.22 | 3.25 | 0.5 | 0.37 | 4.19 | 3.25 | 0.437 | 3.46 | 7.5 | 3.4 |

| 3 | 80 | 3.5 | 3.34 | 0.31 | 0.63 | 3.85 | 2.86 | 0.46 | 1.18 | 3.25 | 0.5 | 0.37 | 4.44 | 3.54 | 0.437 | 3.97 | 8.7 | 3.9 |

| 3 O.D. | 76.1 | 3 | 2.84 | 0.31 | 0.63 | 3.85 | 2.42 | 0.46 | 1.22 | 3.25 | 0.5 | 0.37 | 4.19 | 3.25 | 0.437 | 3.46 | 8.7 | 3.9 |

| 4 | 100 | 4.5 | 4.33 | 0.38 | 0.63 | 4.56 | 3.84 | 0.46 | 1.24 | 3.25 | 0.66 | 0.5 | 5.33 | 4.35 | 0.437 | 5.03 | 12.2 | 5.5 |

| 5 | 125 | 5.56 | 5.39 | 0.38 | 0.63 | 5.86 | 4.79 | 0.46 | 1.24 | 3.25 | 0.66 | 0.5 | 5.83 | 4.84 | 0.437 | 6.27 | 17.3 | 7.8 |

| 6 | 150 | 6.63 | 6.45 | 0.38 | 0.63 | 5.86 | 5.73 | 0.46 | 1.29 | 3.25 | 0.78 | 0.56 | 7.11 | 5.93 | 0.437 | 7.25 | 27.4 | 12.4 |

| 6 1/2 O.D. | 165.1 | 6.51 | 6.32 | 0.38 | 0.63 | 5.86 | 5.73 | 0.46 | 1.29 | 3.25 | 78 | 0.56 | 7.11 | 5.93 | 0.437 | 7.25 | 27.4 | 12.4 |

| 8 | 200 | 8.63 | 8.44 | 0.44 | 0.75 | 5.26 | 7.71 | 0.46 | 1.32 | 3.25 | 0.78 | 0.56 | 8.05 | 6.87 | 0.437 | 9.25 | 32.5 | 14.7 |

| 10 | 250 | 10.75 | 10.56 | 0.5 | 0.75 | 6.29 | 9.56 | 0.7 | 1.38 | 5 | 1.06 | 0.75 | 9.86 | 9.17 | 0.562 | 11.25 | 69.6 | 31.6 |

| 12 | 300 | 12.76 | 12.51 | 0.5 | 0.75 | 6.52 | 11.55 | 0.7 | 1.38 | 5 | 1.06 | 0.75 | 10.85 | 10.17 | 0.562 | 13.14 | 88 | 39.9 |

| PART | SPECIFICATION |

| 1. Upper Stem | Stainless Steel ASTM A582 Type 416 |

| 2. Upper Bearing | Split Metal |

| 3. O-Ring | EPDM |

| 4. Body Ductile | Iron ASTM A395 w/Polyamide Coating |

| 5. Disc Ductile | Iron ASTM A395 w/EPDM |

| 6. Lower Bearing | Split Metal |

| 7. Lower Stem | Stainless Steel ASTM A582 Type 416 |

| 8. Dust Plug | PVC |

| 9. Name Plate | Aluminum |