The NIBCO® wafer type butterfly valve is classified as a fire protection control valve that are Underwriters Laboratories listed and Factory Mutual approved for bubble-tight shutoff at 250 PSI water working pressure. Wafer valves are recommended for quick installation and removal from piping. The NIBCO® ductile iron butterfly valve is designed specifically to meet the rigorous requirements of automatic sprinkler systems. The unique EPDM molded-in seat liner with ductile iron disc provides bubble-tight shutoff at rated pressure. These valves are installed and monitored in fire protection applications where they remain in the normally closed position. A typical application would be fire pump test bypass lines. With the internal stem/disc geometric drive design there is no need for pins or bolts that may create leak paths or turbulence in the waterway. An extended neck allows for insulation up to 2 inches.

OVERVIEW

Valve pressure rating 250 psi wwp Wafer style EPDM molded-in seat liner Designed for normally closed position monitoring Ductile iron disc Stainless steel stem with copper bushings Geometric drive Extended neck Operating mechanism: Manual gear operator Available with (suffix 8N) internal monitor switches UL/ULC Listed FM Approved UL Listed for Indoor and Outdoor Service Conforms to MSS SP-67, MSS SP-25 Size range 2-1/2″ to 8″

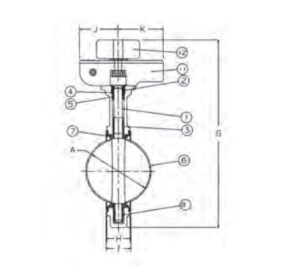

| Size | Dimensions | ||||||||||||||||||||

| A | B | C | D | E | F | G | H | I | J | ||||||||||||

| In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. |

| 2 1/2 | 65 | 2.9 | 74 | 5.62 | 143 | 5.12 | 130 | 5.88 | 149 | 3.25 | 83 | 7.36 | 187 | 13.63 | 346 | 1.81 | 46 | 1.94 | 49 | 2.91 | 74 |

| 3 | 80 | 3.17 | 81 | 6.12 | 155 | 5.5 | 140 | 6.12 | 155 | 3.38 | 86 | 7.6 | 193 | 14 | 356 | 1.81 | 46 | 1.94 | 49 | 2.91 | 74 |

| 4 | 100 | 4.17 | 106 | 7 | 178 | 8.25 | 210 | 6.88 | 175 | 4 | 102 | 8.39 | 213 | 15.38 | 391 | 2.06 | 52 | 2.19 | 56 | 2.91 | 74 |

| 6 | 150 | 6.17 | 157 | 9.25 | 235 | 10.3 | 260 | 8 | 203 | 5.25 | 133 | 9.49 | 241 | 17.75 | 451 | 2.19 | 56 | 2.31 | 59 | 2.91 | 74 |

| 8 | 200 | 8.17 | 208 | 11.6 | 295 | 12.4 | 314 | 9.25 | 235 | 6.5 | 165 | 10.75 | 273 | 20.25 | 514 | 2.38 | 60 | 2.5 | 64 | 2.91 | 74 |

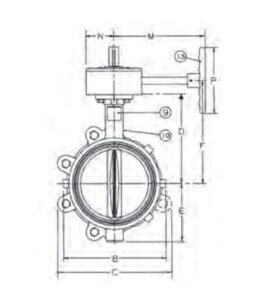

| Size | Dimensions | Flange / Stud Data | Weights | ||||||||||||||||||

| K | M | N | P | Dia | Wafer | Lug | BC | Lug | Wafer | ||||||||||||

| In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | In. | mm. | Lbs. | Kg. | Lbs. | Kg. |

| 2 1/2 | 65 | 3.54 | 90 | 5.82 | 148 | 2.13 | 54 | 5.9 | 150 | 5/8 | 16 | 4.25 | 108 | 1.5 | 38 | 5.5 | 140 | 25 | 11 | 24 | 11 |

| 3 | 80 | 3.54 | 90 | 5.82 | 148 | 2.13 | 54 | 5.9 | 150 | 5/8 | 16 | 4.25 | 108 | 1.5 | 38 | 6 | 152 | 26 | 12 | 24 | 11 |

| 4 | 100 | 3.54 | 90 | 5.82 | 148 | 2.13 | 54 | 5.9 | 150 | 5/8 | 16 | 5 | 127 | 2 | 51 | 7.5 | 191 | 31 | 14 | 27 | 12 |

| 6 | 150 | 3.54 | 90 | 7.64 | 194 | 2.13 | 54 | 5.9 | 150 | 3/4 | 20 | 5.25 | 133 | 2 | 51 | 9.5 | 241 | 40 | 18 | 34 | 15 |

| 8 | 200 | 3.54 | 90 | 7.91 | 201 | 2.13 | 54 | 9.8 | 250 | 3/4 | 20 | 5.75 | 146 | 2.25 | 57 | 11.75 | 298 | 55 | 25 | 49 | 22 |

| PART | SPECIFICATION |

| 1. Upper Stem | Stainless Steel ASTM A582 Type 416 |

| 2. Upper Bearing | Split Metal |

| 3. O-Ring | EPDM |

| 4. Body Ductile | Iron ASTM A395 w/Polyamide Coating |

| 5. Disc Ductile | Iron ASTM A395 w/EPDM |

| 6. Lower Bearing | Split Metal |

| 7. Lower Stem | Stainless Steel ASTM A582 Type 416 |

| 8. Dust Plug | PVC |

| 9. Name Plate | Aluminum |